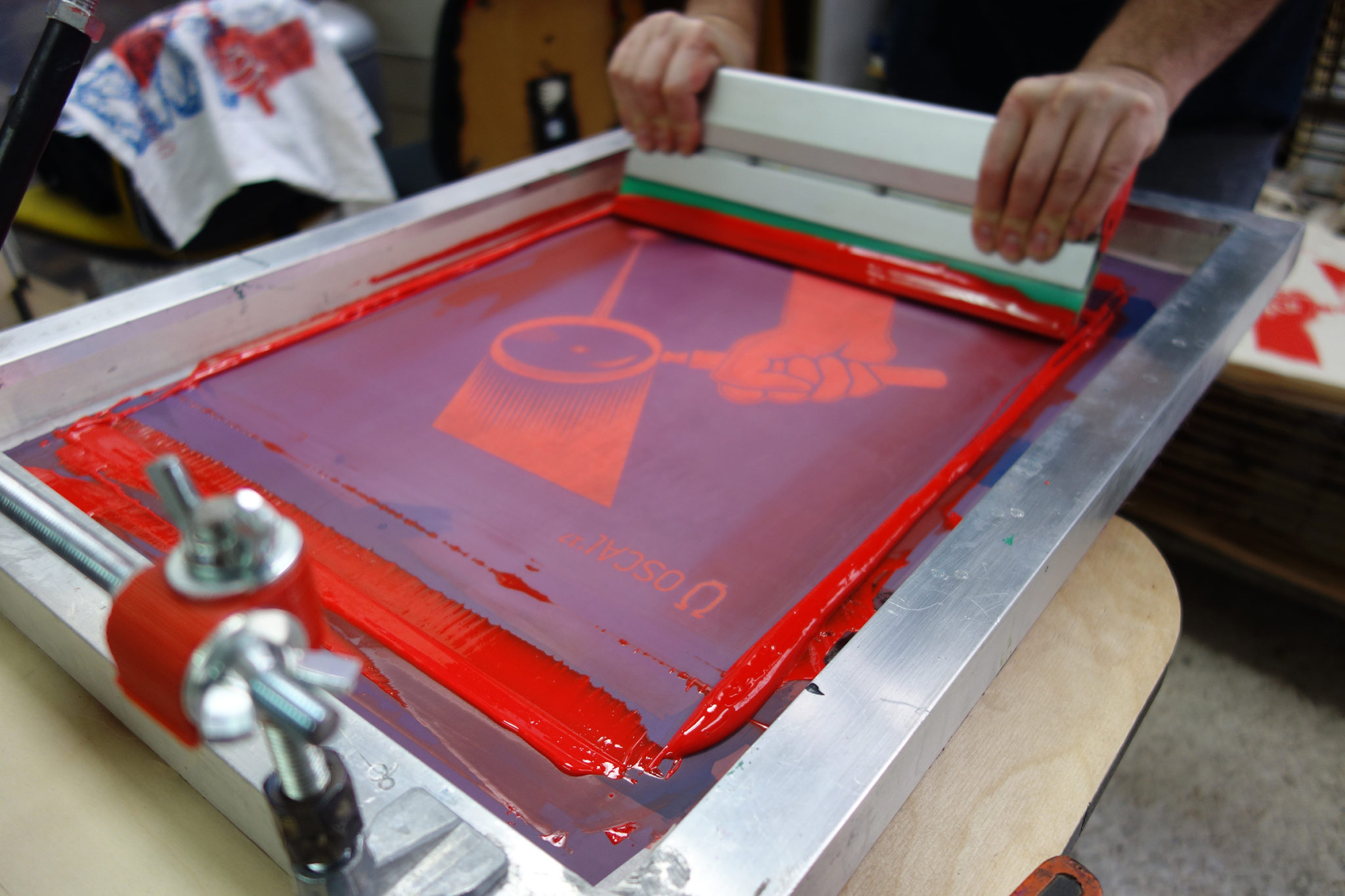

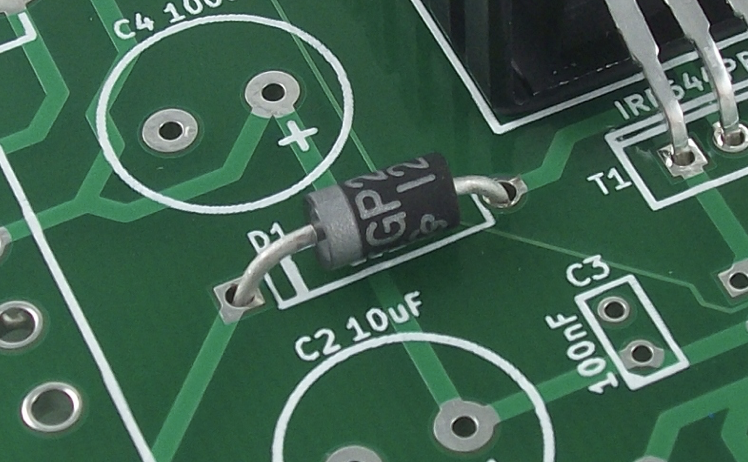

This trio of developers would prove to revolutionize the commercial screen printing industry by introducing photo-imaged stencils to the industry, though the acceptance of this method would take many years. Roy Beck, Charles Peter and Edward Owens studied and experimented with chromic acid salt sensitized emulsions for photo-reactive stencils. Screen printing was largely introduced to Western Europe from Asia sometime in the late 18th century, but did not gain large acceptance or use in Europe until silk mesh was more available for trade from the east and a profitable outlet for the medium discovered.Įarly in the 1910s, several printers experimenting with photo-reactive chemicals used the well-known actinic light–activated cross linking or hardening traits of potassium, sodium or ammonium chromate and dichromate chemicals with glues and gelatin compounds. It was then adapted by other Asian countries like Japan, and was further created using newer methods. Screen printing first appeared in a recognizable form in China during the Song Dynasty (960–1279 AD). The poster shop at Heart Mountain War Relocation Center was operated by Japanese-American internees who used the silkscreen method to design information for the entire center (January 1943) Origins Advanced uses include laying down conductors and resistors in multi-layer circuits using thin ceramic layers as the substrate. The technique is used not only for garment printing but for printing on many other substances, including decals, clock and watch faces, balloons, and many other products. There are also different types of mesh size which will determine the outcome and look of the finished design on the material. There are special-use mesh materials of nylon and stainless steel available to the screen-printer. The most popular mesh in general use is made of polyester. Currently, synthetic threads are commonly used in the screen printing process. Traditionally, silk was used in the process. One colour is printed at a time, so several screens can be used to produce a multi-coloured image or design. This causes the ink to wet the substrate and be pulled out of the mesh apertures as the screen springs back after the blade has passed. A blade or squeegee is moved across the screen to fill the open mesh apertures with ink, and a reverse stroke then causes the screen to touch the substrate momentarily along a line of contact.

Screen printing (traditionally called silkscreen printing also known as serigraphy and serigraph printing) is a printing technique where a mesh is used to transfer ink (or dye) onto a substrate, except in areas made impermeable to the ink by a blocking stencil.

0 kommentar(er)

0 kommentar(er)